Machines Used in Wall Putty Manufacturing

Wall Putty Manufacturing Machine

Wall Putty Making Machine | Automatic Wall Putty Plant

Manual Wall Putty Manufacturing Machine

Cost-effective solution for small-scale wall putty production

Ribbon Blender

Ribbon Blender for Dry Wall Putty and Powder Mixing

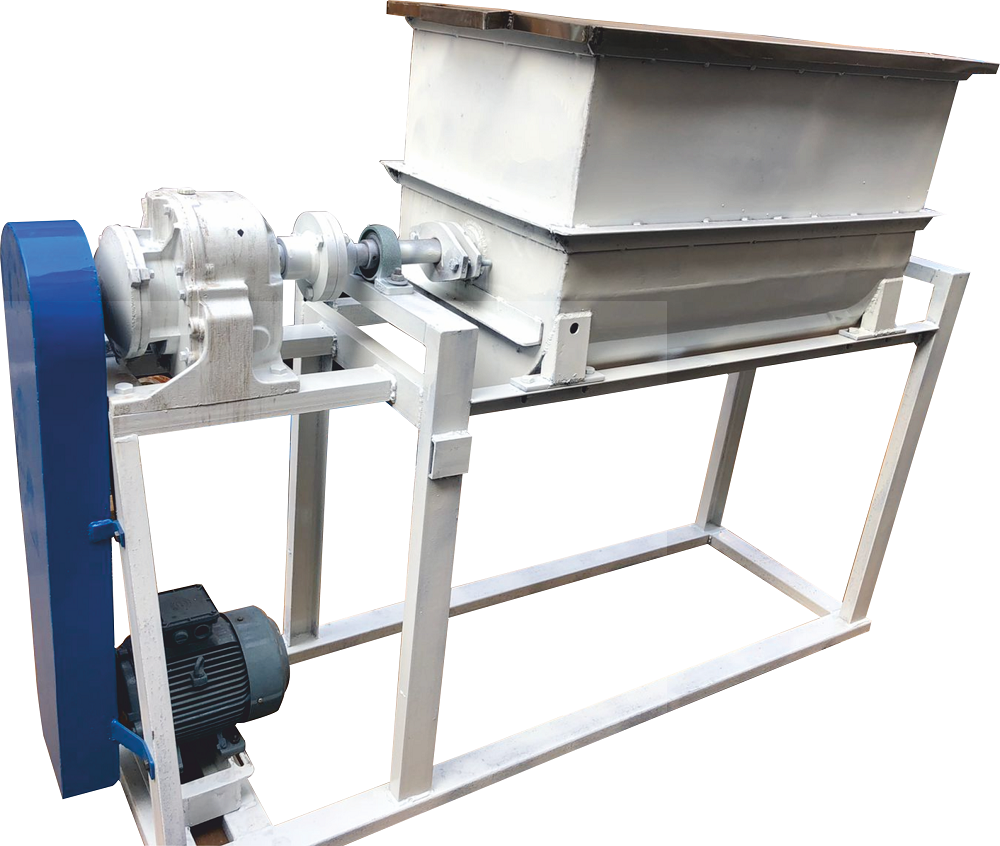

Twin Shaft Mixer

Industrial Twin Shaft Mixer for Wall Putty

Dry Mix Mortar Machine

Dry Mix Plant for Wall Putty & Cement-Based Mortars

Tile Adhesive Machine

For Cementitious Wall Putty, Tile Fix & Adhesives

High Speed Disperser

For Wall Putty Premix, Color Paste & Additives