Plant Setup • Formula • Raw Material • Costing • Trial Support

If you are planning a wall putty unit, we help you with process planning, putty formula, raw material requirement, unit costing, and setup execution. Machines come last—recommended only after process finalization.

Wall Putty Manufacturing is a forward-thinking initiative committed to enabling eco-conscious and profitable wall putty production. Backed by Indian Paints Consulting Services (IPCS), we empower entrepreneurs to establish high-quality wall putty plants with low investment and high returns.

We offer a complete solution including wall putty mixing machinery, tested formulation support, and consultancy for plant setup. Our expert team provides end-to-end guidance — from machinery to marketing — to help you succeed in the construction materials industry.

To get started, contact us at +91 82104 79182 or visit www.wallputtymanufacturing.com. Your journey toward a profitable wall putty business begins today.

Wall Putty Making Machine | Automatic Wall Putty Plant

Cost-effective solution for small-scale wall putty production

Tile Adhesive | Readymix Plaster | Dry Mortar | All products Making Machine

Dry Mix Plant for Wall Putty & Cement-Based Mortars also works for all products

For Cementitious Wall Putty, Tile Fix & Adhesives

Process • Formula • Raw Material • Costing • Trial Support

Our consultancy helps you start production with clarity and confidence. You get planning, practical guidance, and technical support to build a stable, sellable wall putty product.

Complete process flow from raw material handling to mixing, packaging, storage and dispatch—simple and practical.

Support to develop formula based on target quality—smoothness, whiteness, coverage, workability and performance.

Material list, approximate usage guidance, storage planning, and quality checkpoints to avoid common mistakes.

Unit costing understanding, packaging cost factors, wastage control, and margin planning for market-fit pricing.

Guidance for QC checks and troubleshooting issues like lumping, poor whiteness, low coverage or inconsistency.

Trial batch planning, operating guidance and training framework for repeatable production and consistent quality.

Clear steps • No confusion

This roadmap explains how consultancy works—from planning to first successful production—so you know what happens next.

Capacity, budget, location, goals—clear direction set at the start.

Workflow for handling, mixing, packing and storage—planned for smooth operations.

Define product grade and performance expectations (finish, workability, coverage).

Material list, usage guidance, handling/storage checkpoints and sourcing checklist.

Cost drivers, wastage control and margin planning for realistic market pricing.

Trial batch guidance, troubleshooting and final SOP for stable repeat production.

Best fit • Expected results

This section helps you quickly understand whether consultancy is right for your situation and what outcomes you can expect.

• New entrepreneurs planning a wall putty unit

• Existing manufacturers improving quality/margins

• People facing batch inconsistency or quality issues

• Anyone who wants a clear roadmap before investing

• Clear process plan & production workflow

• Standardized formula with defined quality targets

• Better control on raw material and costing

• Fewer production errors and stable batch quality

• Ready-to-scale approach with SOP + QC checks

Wall Putty Manufacturing is a premium service by Indian Paints Consulting Services (IPCS), providing end-to-end support for launching your own wall putty production unit. Whether you're looking for wall putty formulation, plant setup guidance, semi-automatic or fully automatic machines, or low-investment startup ideas — we are your trusted partner. Start your journey towards high-margin, in-demand construction products with IPCS today.

End-to-end expert guidance to set up wall putty manufacturing with machinery, formula & plant design.

Affordable and scalable setup options for semi-auto and fully automatic wall putty units across India.

High-quality putty formulas (white cement based, acrylic, polymer-enhanced) tested for commercial use.

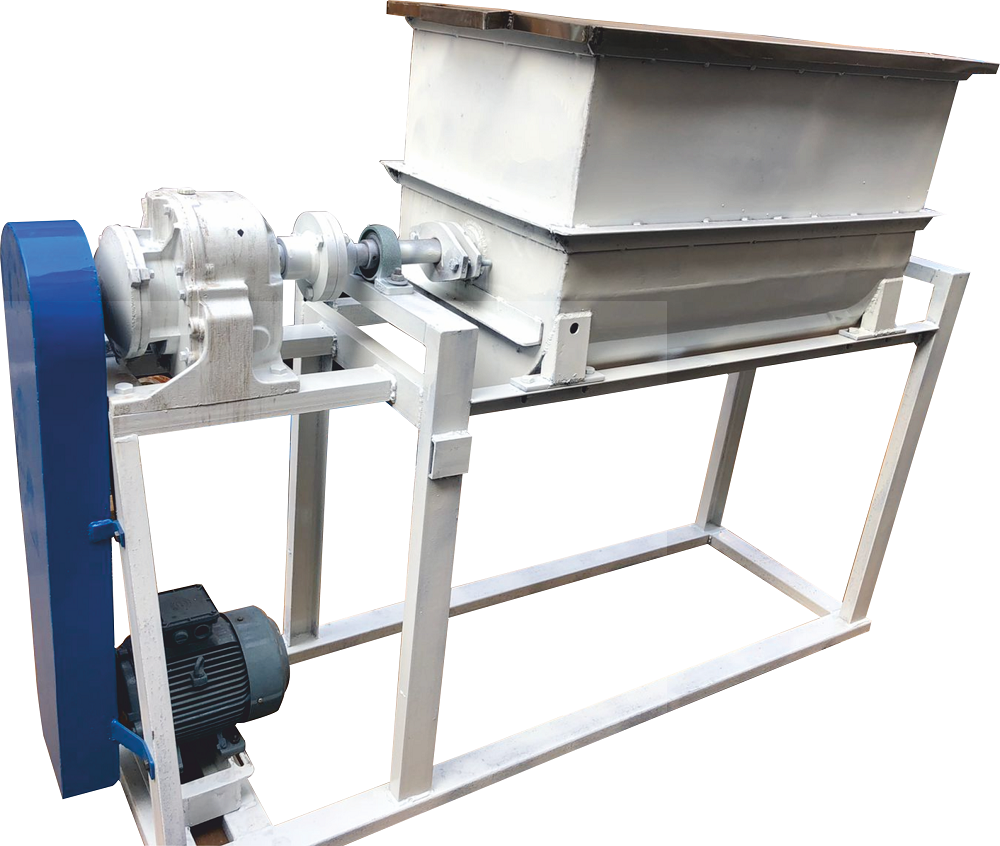

Customized machines like ribbon blenders, silos, screw conveyors, and packaging lines available.

Start a profitable wall putty unit with minimal investment — includes setup, training & formulation.

Modern brand identity design, attractive bags/labels, and logo creation for your wall putty brand.

Practical on-site and online training for putty formulation, mixing, quality control, and packaging.

Get assistance for ISO, BIS (ISI mark), and environmental clearance for wall putty manufacturing.

Automated systems for batch mixing, storage silos, and pneumatic conveying to reduce labor costs.

Reliable sourcing for white cement, dolomite, polymers, preservatives, and dispersing agents.

Machines for precise filling of wall putty into 20kg/40kg/50kg bags with sealing & weighing systems.

Tailored end-to-end plant setup including layout, ROI planning, equipment integration & marketing.

ISO 14001 Certified

ISO 45001 Certified

ISO 9001 Certified

MSME Certified

GeM Registered

Wall Putty is a white cement-based finishing material applied on plastered walls to create a smooth surface before painting. It improves paint adhesion, surface texture, and durability.

Yes, it is a highly profitable business due to increasing demand in both urban and rural construction markets. With the right formula and setup, ROI can begin within a few months.

A small-scale wall putty plant can be started with ₹5 to ₹8 lakhs including machines, setup, raw materials, and consultancy.

You’ll need a Ribbon Blender, Weighing System, Dust Collector, Packaging Machine, and Pulverizer for full-scale production. IPCS provides machinery with training and installation support.

Common ingredients include white cement, dolomite powder, polymers, preservatives, and cellulose. IPCS helps you with quality sourcing and local vendors.

Yes, you'll need MSME Udyam Registration, GST number, Pollution NOC, and optionally BIS/ISO certification depending on market goals.

Yes, IPCS offers hands-on training in real production environments. This includes raw material selection, formulation, blending, packaging and marketing tips.

Yes, IPCS provides ready-to-manufacture, tested formulas for white cement-based, polymer-based, and waterproof wall putty variants.

Contact IPCS via wall-putty manufacturing service page or call +91 82104 79182 for complete turnkey assistance.

Indian Paints Consulting Services (IPCS)

Phone: +91 82104 79182

Phone: 1800-572-2386